M-Series

M-Series dryers are compact, high-performance, and programmable drying solutions which are ideal for high speed inkjet drying and the drying, sintering, and curing of conductive or resistive of inks and coatings. The M-series product line utilizes patented adphosNIR® technology and offers more options, higher productivity, and easier integration while offering a return on your investment in as little as three months. The M-series product line offers a variety of emitters to meet a wide range of applications. Lower powered emitters for mailbases, binding lines, and other sheet-fed converting equipment and higher powered emitters for high speed web-fed applications. Additionally, adphos M-Series provides high-end status indication for input signals and error management for ease of use and user-friendless.

More Options

Lower powered emitters are ideal for sheet fed applications on porous and coated substrates at speeds up to 330 fpm. Medium powered emitters are suitable for sheet fed or web fed applications on high gloss, over-coated and plastic substrates at speeds up to 650 fpm. The M3 is also programmable and upgradeable to an M4 configuration and offers USB connectivity for integration flexibility with third party transports and finishing lines. The M4 is a higher powered version of the M3 and offers the highest energy densities for ultra high speed web applications on mill coated and aqueous over-coated substrates at speeds in excess of 1,000 fpm. Additional options include Air Filter, Exhaust Plenum, Tachometer Kit, Light Shield, and WINNIR Software.

Integration flexibility

M-Series dryers as the world’s first “Smart Dryers” with USB connectivity and programmability, M-Series dryers allow for seamless electrical integration to third party transports and permit tailored performance to meet your specific requirements. Modularity allows for multiple dryers to be daisy-chained together to operate as a single system. The compact “one-piece” design provides the ability to mount the dryer in almost any orientation for placement nearly anywhere.

Lower Cost

adphosNIR® technology is now offered at a lower investment cost. So you can now own a superior adphosNIR® dryer for less than other lower performing systems. With less power consumption and less “thermal strain” on transports and belts, M-Series dryers pro- vide a lower cost of operations than other systems.

Customer Testimonial

“adphosNIR® dryers have given Rees over three times the speed on glossy stocks with a 48% reduction in our electricity which provided an ROI of less that 60 days.”

Rick Fitsimmons, Rees and Associates

“Thanks to adphos, increases in throughput and additional capabilities have helped balance both the sales and production sides of our business.”

Niels Winther, Think Patented

Interested in more customer testimonials? Visit here to view all the customer testimonials.

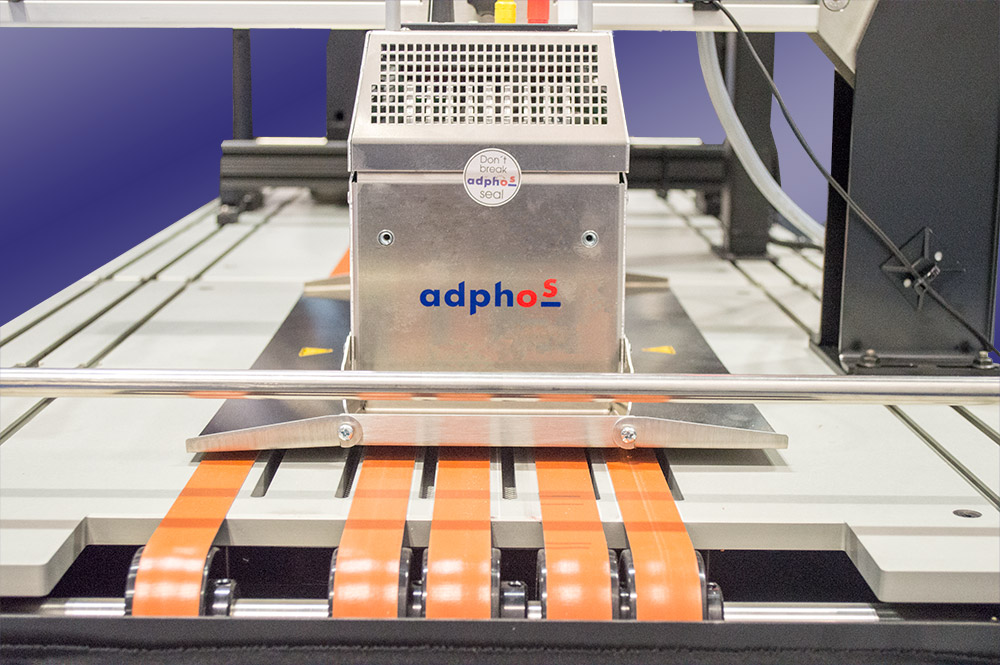

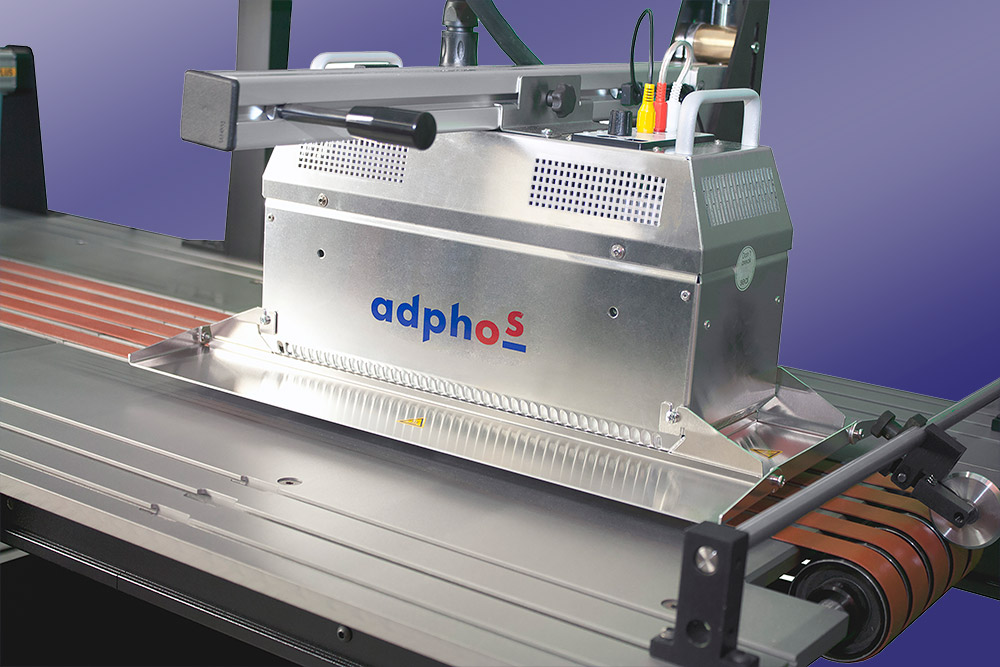

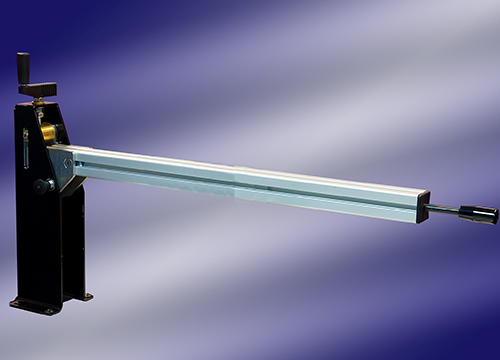

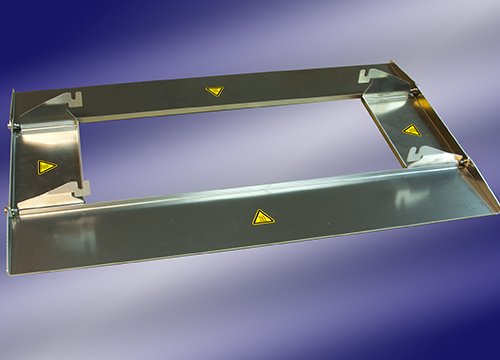

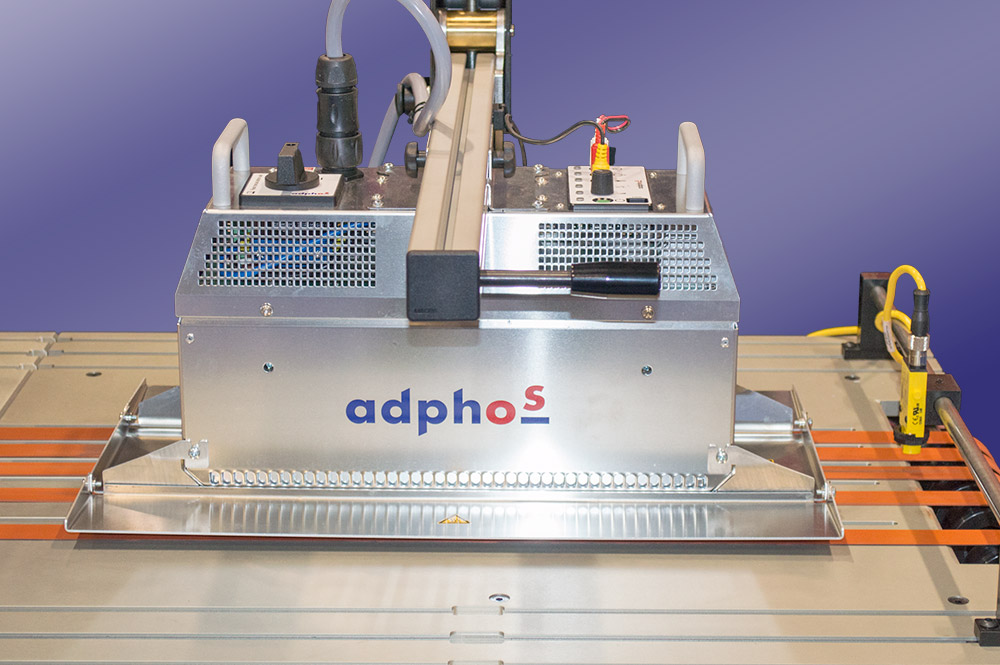

Equipment Photos