Graphic Arts

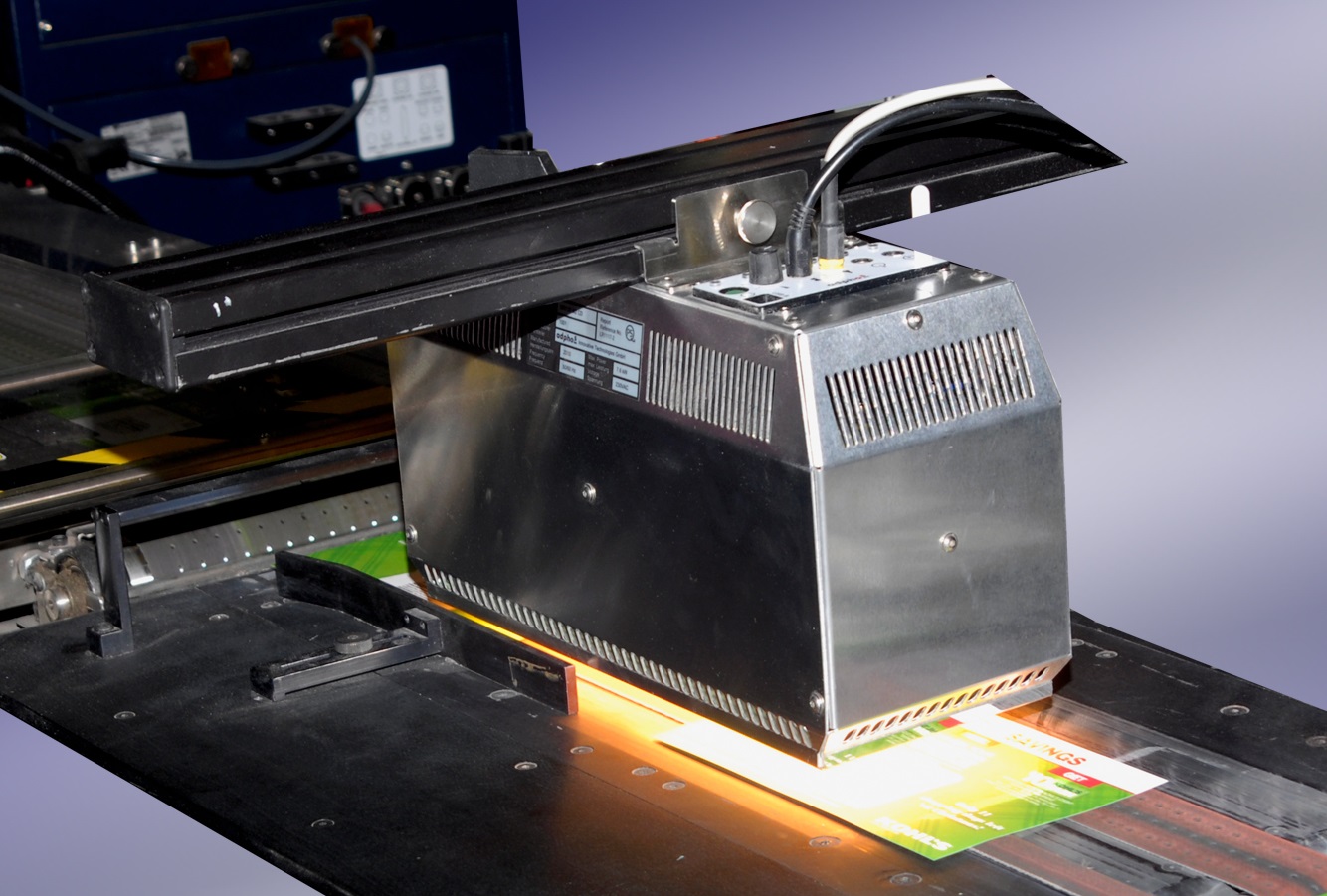

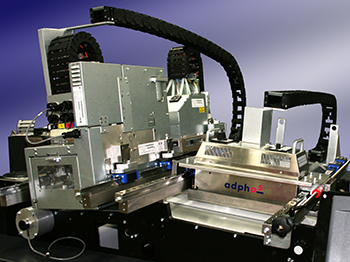

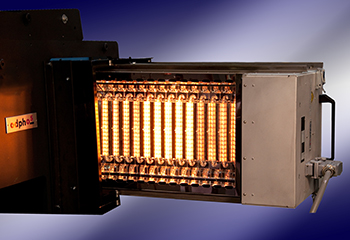

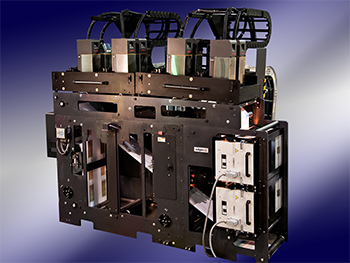

adphosNIR® systems are perfect for increasing productivity and print quality enhancement for Digital, Conventional, or Hybrid Printing applications in the Graphic Arts market including upgrades, retrofits, or replacements of existing drying systems for digital inkjet presses, hybrid (conventional/digital) printing presses and finishing lines.

Advantages of adphosNIR® technology for Graphic Arts:

- Lower total cost of operation (TCO) through:

- Greater speed, productivity and throughput

- Less energy required compared to other systems

- Reduced scrap through highly responsive system operation

- With the minimal effects of adphosNIR® on substrates (Heating, Cockle and Curl), greater productivity on finishing lines are achieved

- Higher quality finished products (Direct Mail, Books, Publications, Statements)

- Less substrate cockle and curl through minimal thermal stress

Applications:

- Drying of water based inkjets ink up to 3,000ft/min (915m/min)

- Drying of inks on temperature sensitive substrates – including plastics

- Specific booster drying solutions for your already installed inkjet printing press(es)

- Integrate monochrome, spot or process color inkjet with traditional web presses and finishing lines

- Experienced with integration of all inkjet technologies – continuous, piezo, and thermal

- Solutions include print head carriages, inkjet dryers, and towers

- Wide variety of options including web management and inspection are available

- High speed drying of aqueous pre or post – coat solutions

- Ideal for drying of water-based adhesives (Envelope Gum)

Want to learn more about how adphos can benefit your company? Click here.