In a thin-strip plant of a leading international American steel group, a Castrip-plant has been upgraded with an aNIR® heating booster and put back into successful commercial production operation for improved “hot roll quality” after only one week of commissioning.

Thanks to the aNIR® (advanced NIR)-technology based photonic high-performance heating booster “NIR-Rollheater 1800” developed by adphos, local temperature differences caused by impurities before the quenching rolls are corrected and a homogeneous temperature distribution is achieved, resulting in significant improvements in product quality.

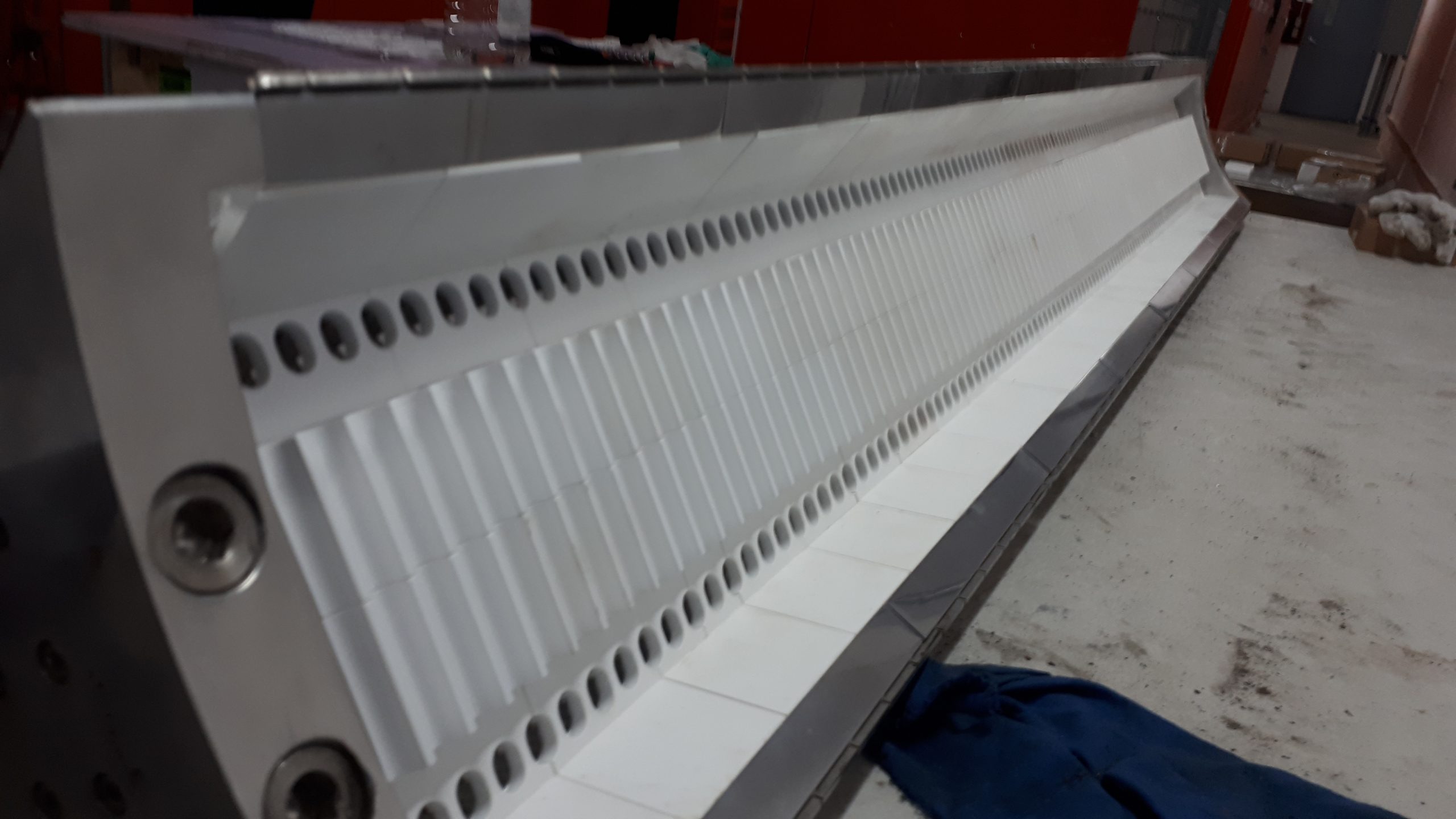

Only the possible high-power density (1,600 kW/m2), as well as the locally adjustable heating power across the web width (at intervals of only 15 mm (!) and on both sides of the steel web, make this possible in a defined, controlled and automated manner, at production speeds of up to 150 m/min. The special and robust aNIR®-design, which is used in extremely confined spaces at ambient temperatures of up to 350° C and with the unavoidable local contamination, makes the system so unique. No other technology (e.g. laser, induction, …) has been able to implement such a production-suitable system.

adphos offers further high-performance thermal process solutions for heating and drying process solutions for heating and drying processes for surface coatings in the steel sector. All adphos solutions are based on the company´s proprietary aNIR®-technology, a high-performance photonic energy source that achieves spontaneous drying in combination with tempered impingement air. The aNIR®-solutions are purely electro-thermal and, therefore, completely CO² emission-free.

For more information, please contact info@adphos.de