Graphic Arts

adphosNIR® systems are perfect for increased productivity and print quality enhancement for Digital, Conventional, or Hybrid Printing applications including upgrades, retrofits, or replacements of existing drying systems for digital inkjet presses, hybrid (conventional/digital) printing presses and finishing lines.

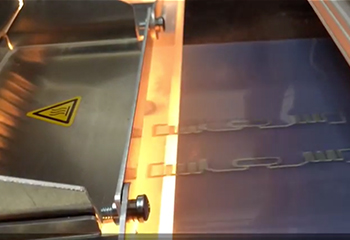

Printed Electronics

adphos technology can be used for a wide variety of thermal processes including drying, curing, sintering and annealing. Applications include drying of high speed inkjet inks, water-based coatings and adhesives within the graphic arts market. Within industrial markets adphos technology can be used for the curing of powder coats and for sintering metalic inks for printed electronics (PE) applications.

Coil Coating

For coil coating applications, adphosNIR® technology allows for faster production speeds and start-up times while providing a reduction in energy consumption and scrap. All of this is achieved while providing a smaller footprint and a significant reduction in the overall size of the coil coating line.

Automotive

Significant production efficiencies can be realized in the automotive industry through the drying of paints and over-coats as well as the drying and curing of adhesives and powder-coats commonly used in the automotive industry. The applications vary from heating up of substrates to drying and curing of lacquers and coatings.

PET Preform Heating

For PET blow molded bottle production adphosNIR® provides a much more accurate profile of the pre-form surface than with any other technology allowing a significant reduction of PET material.

Industrial

The use of adphosNIR® technology for the drying and curing of coatings, inks and adhesives as well as the vulcanization of rubber, have provided significant breakthroughs and quantum leaps forward in terms of reduced processing times, increased production speeds and overall productivity in a wide variety of industrial applications.