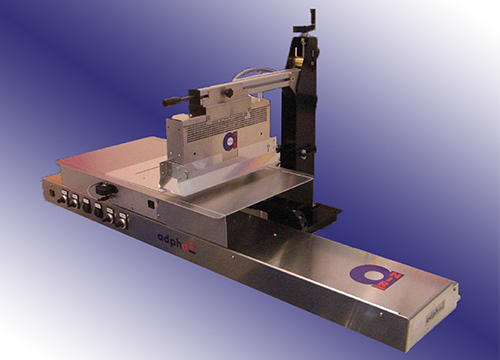

PBT (Platten Based Transport)

adphos PBTs (Platen Based Transports) are companion products for x-y inkjet plotters. PBTs allow for “production” drying, sintering and curing in a lab scale device. PBTs are available in two configurations with both stationary and motor driven platens. Both systems include vacuum plate (and air hold down) to maintain product integrity during processing.

Lab Testing to Full Production

Moving from printed electronics concepts in the lab to full production can involve great risks of manufacturability. Products that are currently produced on an x-y machine can now be evaluated on a low cost, high speed transport to simulate your actual production process.

Maximum Adaptability

PBTs provide an open interface to various inkjet heads including: FUJIFILM Dimatix, Hewlett Packard, Kyocera, Konica Minolta and others.

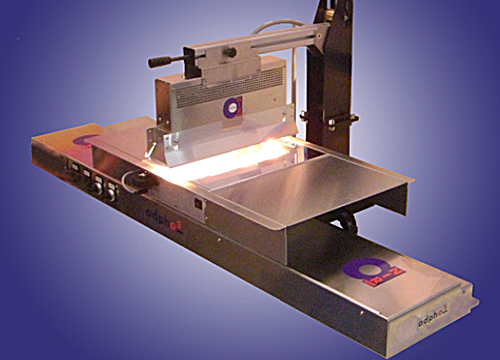

A large selection of adphosNIR® drying, curing and sintering equipment is available for integration with all models of the R2R-from high performance adphosNIR® combined with hot air for drying applications to focused reflectors for high density, short duration photonic processing (sintering/annealing). Please consult Adphos for different options appropriate for your application.