Videos

The videos below are linked to an external website. By clicking on the link, you will be redirected to an external website where you may be subject to their privacy policy and data collection practices. Please review their privacy policy to understand how your data is handled when visiting the external website.

The ArrowJet Aqua 330 Pigment-Based Digital Printer Debutted with adphosNIR Dryers

The video demonstrates the Memjet Duraflex-based print engine used in Arrows Aqua 330R combined with an impressive adphos dryer for high quality output and low overhead cost.

Kodak Prosper Ultra 520 Press with Adphos Technology

Kodak introduces the Ultra 520 Inkjet Press which features adphos aNIR drying technology

Watch The Kao Collins And adphos Partnership In Action

Watch how the adphosNIR® technology helped expand the performance of the 3600 series system.

Watch how the adphosNIR® technology helped expand the performance of the 3600 series system.

Demonstration at Convertech2020 in Tokyo – Instantaneous Sintering Conductive Ag Paste with adphosNIR®

- Emiter Power: 2.1 kW x 100%

- Dwell Time (passing under 250mm emitters) – PET Film: 15mpm (1 sec) x 3 times, Paper: 20mpm (0.75 sec)

Sintering of the same Ag paste with hot air oven takes 20 min at 130 degrees C.

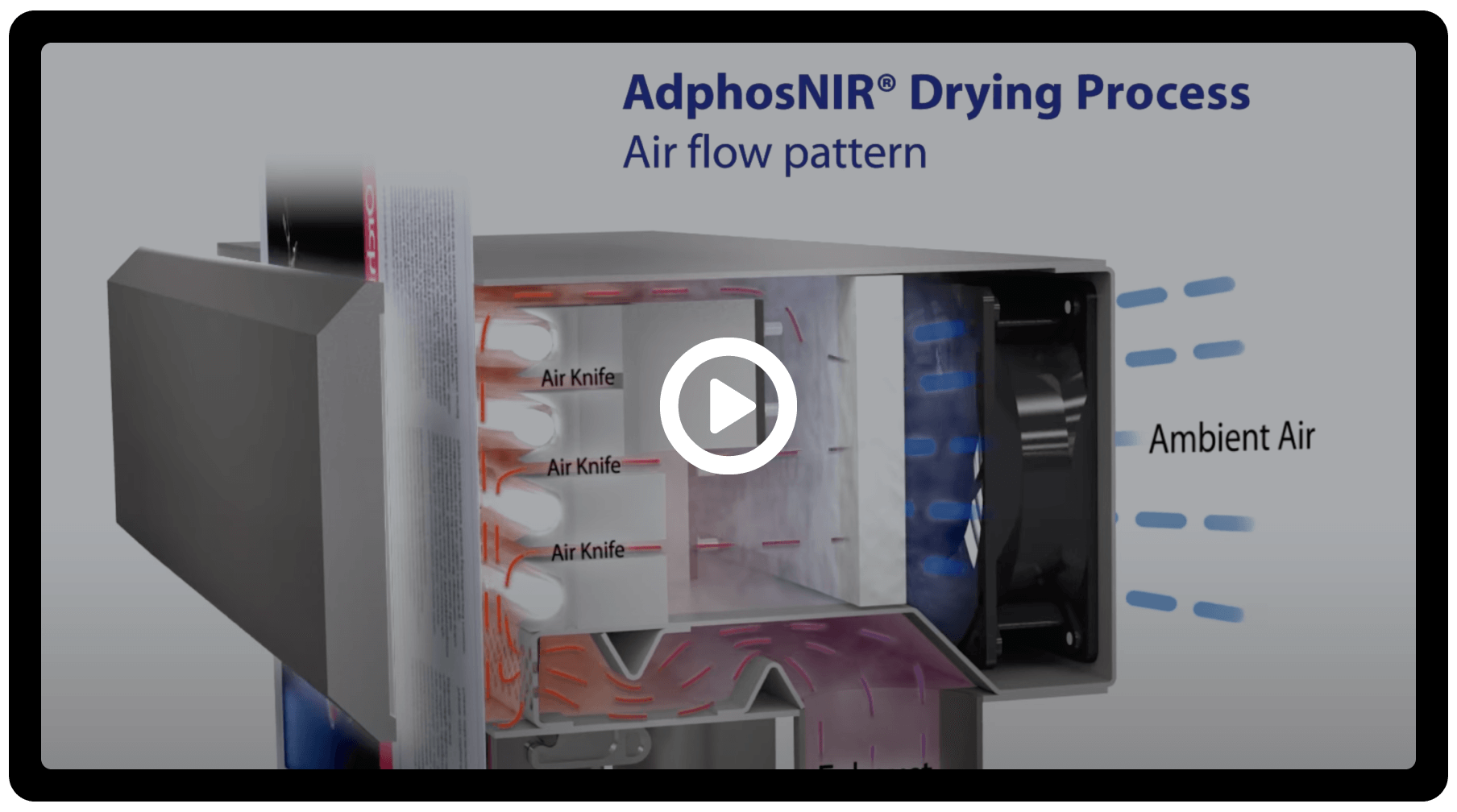

adphosNIR® Technology Helps Take Inkjet Printing Offset

Watch how the partnership between the Screen Truepress Jet 520HD+ and adphosNIR® technology helps take inkjet printing offset.

Watch how the partnership between the Screen Truepress Jet 520HD+ and adphosNIR® technology helps take inkjet printing offset.

Interview with President Dr. Bär

Dr. Kai Bär of the adphos Group is a leading expert on NIR (Near Infrared) Drying, Curing and Sintering. Elizabeth Gooding had the opportunity to sit down with him and talk about the role that drying technology plays in achieving quality output with production inkjet.

Dr. Kai Bär of the adphos Group is a leading expert on NIR (Near Infrared) Drying, Curing and Sintering. Elizabeth Gooding had the opportunity to sit down with him and talk about the role that drying technology plays in achieving quality output with production inkjet.

adphosNIR® in HP T-Series inkjet Presses

Watch how adphosNIR® can help to improve the performance of HP T-Series Presses by adding boosters or replacing existing dryers by adphosNIR® systems.

Watch how adphosNIR® can help to improve the performance of HP T-Series Presses by adding boosters or replacing existing dryers by adphosNIR® systems.

M-Series Dryers

Watch how adphos can help to improve the throughput of your print shop by using adphosNIR® M-Series dryers.

Watch how adphos can help to improve the throughput of your print shop by using adphosNIR® M-Series dryers.

adphos Tower Solutions

Here are some examples of benefits our partners have achieved after partnering with adphosNIR® technology:

“With the adphos NIR®120, I am now able to image at fully rated inkjet speeds over twice the throughput on high gloss and aqueous coated papers.”

Tammy Caserta, Director of Mailing Services

“Thanks to adphos, increases in throughput and additional capabilities have helped balance both the sales and production sides of our business.”

Niels Winther, Chairman and Managing Partner

“With adphos inkjet drying, we can say “Yes” to our customers and prospects more often.”

Ken McNerney, CEO and Managing Partner

Want to learn more about how adphos can benefit your company? Click here.