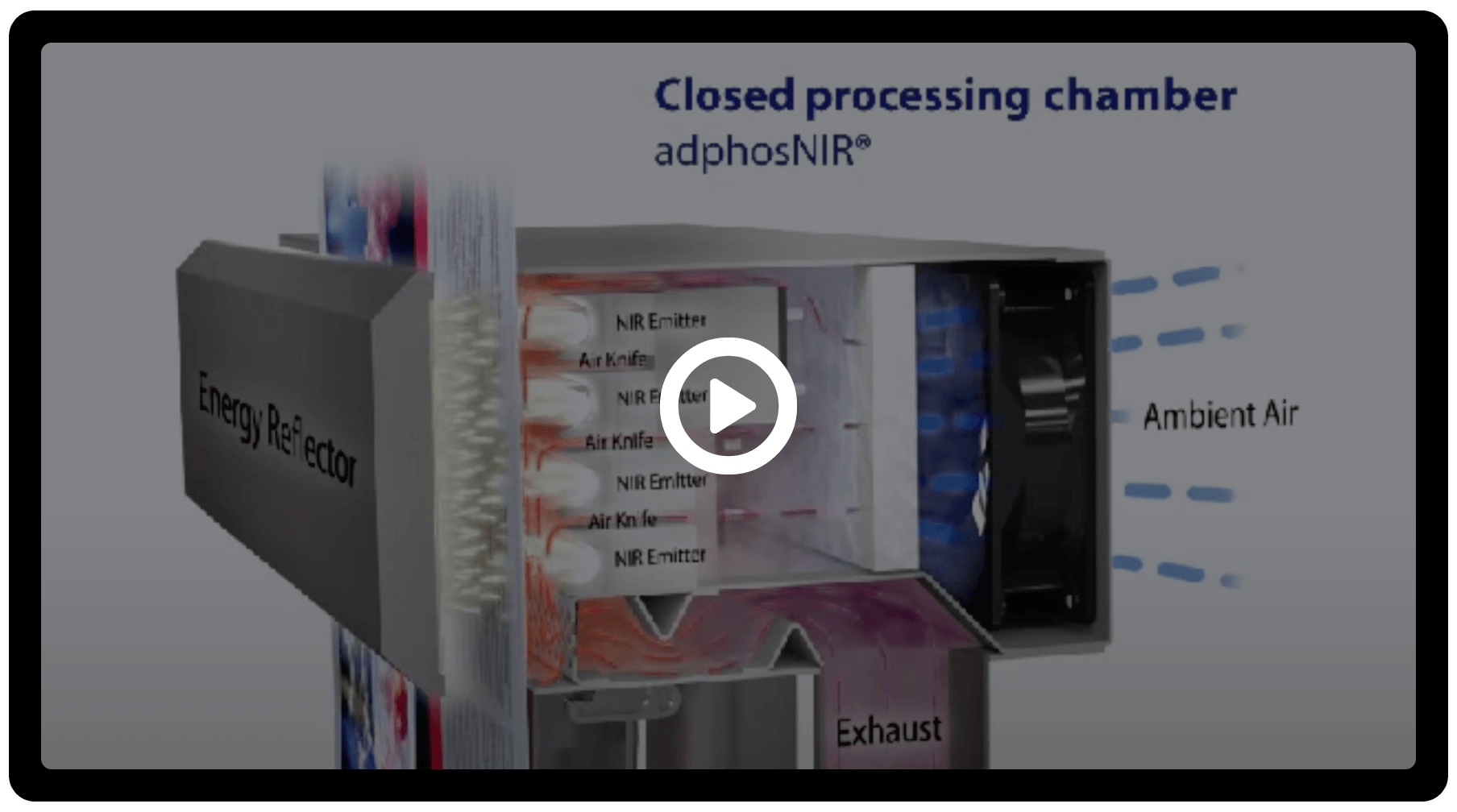

adphosNIR® technology

The adphosNIR Technology is a combination of near-infrared (NIR) light energy, management of the NIR energy, integrated hot air knives and moisture extraction.

The video above is linked to an external website. By clicking on this link, you will be redirected to an external website where you may be subject to their privacy policy and data collection practices. Please review their privacy policy to understand how your data is handled when visiting the external website.

The video above is linked to an external website. By clicking on this link, you will be redirected to an external website where you may be subject to their privacy policy and data collection practices. Please review their privacy policy to understand how your data is handled when visiting the external website.

The underlying principle of adphosNIR® technology resembles the way a microwave oven works. Microwaves activate the water molecules directly, in contrast to a conventional oven that has to heat up the substrate before the energy reaches the target, the water or solvent molecules. The electromagnetic waves of the adphosNIR technology have the highest energy densities, which effect molecules of various substances. As a result, adphosNIR® technology can be implemented in a multitude of industrial processes and market places.

Printing – Function of the adphosNIR® technology

There are two phenomena arising when using adphosNIR technology for drying of inkjet printed on paper. The ink has a high absorption and the paper has a high transparency of adphosNIR® radiation.

The ink absorbs the energy and will be dried within seconds with minimal thermal effect on the substrate, thereby in most instances eliminates the need to cool the substrate. energy is only effective where it is necessary. So the need for cooling the paper is almost eliminated.

Varnishes & Lacquer – Function of the adphosNIR® technology

adphosNIR® radiation quickly enters into the depth of the coating to remove the water and solvents from the entire thickness of the coating. With conventional infrared and hot air technologies, the energy is absorbed at the surface and is then slowly conducted into the coating.

There is a similar process with powder coatings and plastics. The powder is heated, melted and cured over through the entire thickness of the coating. As there is no conduction of heat required using adphosNIR technology, powder coatings can be melted and polymerized within seconds instead of minutes.

Plastics – Function of the adphosNIR® technology

In the adphosNIR® wavelength range, most plastics have a high radiation transparency. The beams immediately penetrate deeply and heating is performed rapidly and evenly with extremely short processing times. There is also a clear reduction in energy consumption because the system does not have to be preheated. What is more, it takes up a lot less space. Shorter heating paths also enable optimum integration into production machines and equipment. An integrated control loop also reduces the number of rejects produced.

When heating plastics, adphosNIR® radiation achieves more or less uniform levels of penetration. Infrared radiation essentially heats the surface, from which heat is then transferred.

Want to learn more about how adphos can benefit your company? Click here.