Complex multilayer production process consisting of electronical and insulation conduction layers, anode/cathode layers, sealings and electrolyte paste based layers, either solvent or water-based, with wet coating thicknesses between a few microns (≤ 15 µm) up to several hundred (even ≥ 500 µm) are dried and sintered with coatings/layers adapted aLITE® process steps, all within one-digit seconds (even partially ≤ 1 s). The conventional drying and post-processing´s (heat and/or sintering) for these coatings would require minimum 30 s up to several minutes. The tremendous space savings (up to factor >> 10!) of the coupled multilayer production, thanks to the aLITE®, is evident.

In addition to the possible instantaneous inline quality-controlled drying/post-print process, the lowest tolerance, reliable low waste high production can be ensured.

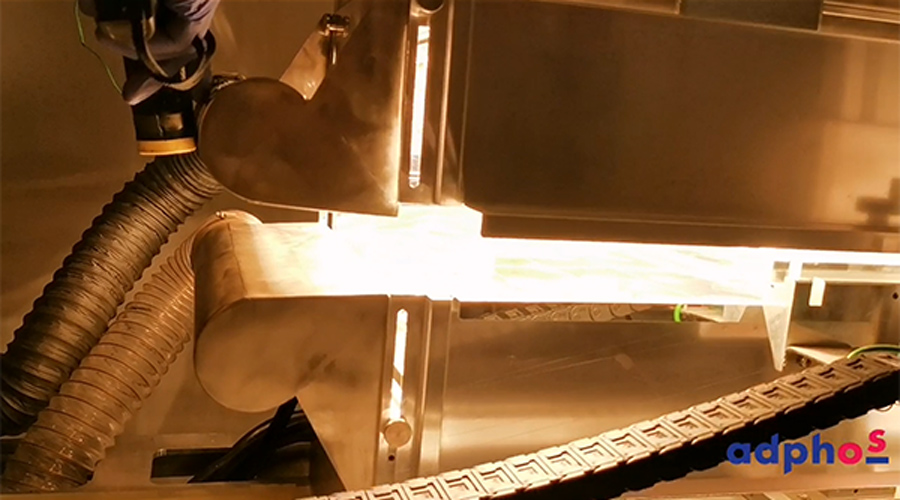

adphos offers with its company proprietary aNIR® (advanced NIR) and aLITE® (advanced Light Initiated Thermal Emission) technologies, adapted and optimized drying/post-coating processes for mono/multilayer productions for a wide range of capacitors, batteries and electrical components. From lab to fab – drying/post-process solutions, ready to integrate in wet and solid coating productions, everything is possible!