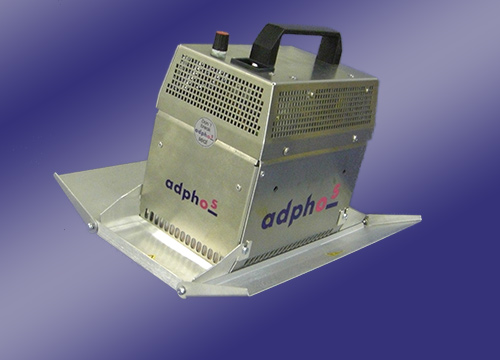

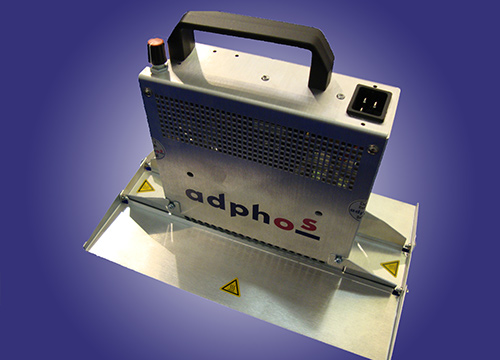

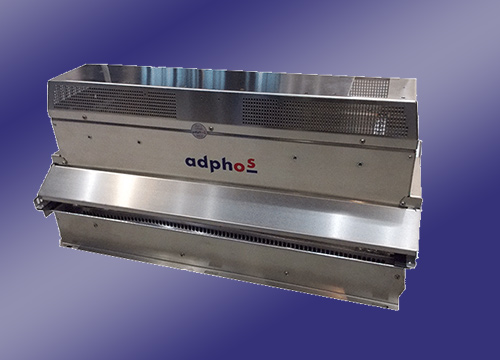

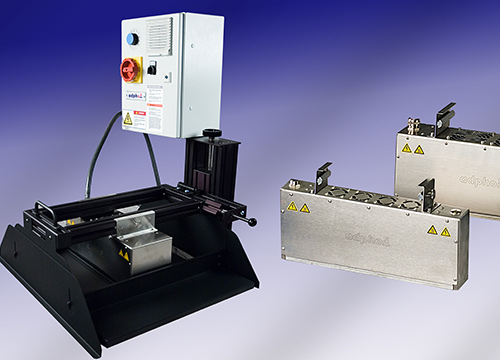

NIRxx Family

The NIRxx Family are cost effective, high performance drying systems for water based continuous and drop-on-demand (DOD) inkjet systems which provide greater productivity and flexibility with reduced operating costs compared to traditional infrared drying systems.

Productivity

With NIR inkjet drying systems you are assured greater productivity and throughput on even the most demanding of water based inkjet applications including those on high gloss, overcoated and temperature sensitive substrates. NIR inkjet drying systems deliver the energy you need, where you need it by utilizing near-infrared technology which focuses the energy on the ink and not on the substrate resulting in less curl and easier to run and handle substrates.

Flexibility

To accommodate a variety of different printhead widths, NIR systems come in three standard drying sizes and can be mounted on sheetfed or web based transports for in-line, near-line, or off-line inkjet applications. With a small footprint and the ability to mount the drying modules in any position, NIR systems offer the utmost in configurable options to change and grow with your business.

Reduced Operating Cost

Depending on your requirements, NIR inkjet drying systems can reduce your electrical expenditures for inkjet drying by more than 70 % because the NIRxx Family utilize ultra-efficient NIR energy and a patented reflector system which reflects >98 % of the energy to where it is needed.

Customer Testimonial

“With the adphos NIR120, I am now able to image at fully rated inkjet speeds with over twice the throughput on high gloss and aqueous coated papers.”

Tammy Caserta, Think Patented

“We would like to convert every one of our (existing) inkjet lines to use adphos dryers.”

Bill Nichols, Bluegrass Mailing

Interested in more customer testimonials? Visit here to view all the customer testimonials.