Coil Solutions

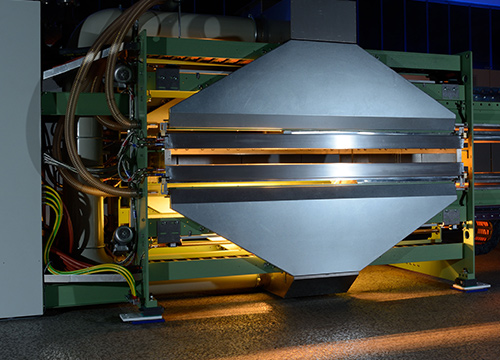

Coilcure systems are designed for quick drying and curing of coatings on metal strips.

These systems are providing the following advantages compared to conventional solutions:

- • Reduced energy consumption possible

- • Reduced cooing possible

- • Reduced space requirements due to compact line design

- • Chemcoatings drying time from 0.1 s – 0.3 s instead of 5 s – 10 s with a PMT from 40 °C – 60 °C instead of 70 °C – 90 °C

- • Primer / Base Coat drying time up to 2 s – 3 s instead of >20 s => drying length 6 m instead of >40 m

- • Top Coat (20 µm – 25 µm) drying time up to 3 s – 4 s instead of >20 s => drying length 8 m instead of >50 m

- • Vertical strip run possible

- • Refitting of an Inline-Paint-Section in an existing line possible

- • No dummy coil necessary for coil thickness- or width changes => less scrap

- • Solvent concentration controlled process possible => reduced energy consumption of VOC destruction system

- • Use of almost all conventional coatings possible

- • Absolutely applicable for solvent based coatings

- • Booster solutions for existing lines possible

Applications

- • Drying chemcoatings

- • Drying lubricants

- • Drying anti-finger-print

- • Drying primer and top coatings

- • Rinse water drying after water cooling zones

- • Heating of metal strips

- • Booster for existing lines

Related products from adphos

- • Heat-exchanger-pump-unit

- • Water cooling unit

- • Squeegee Rolls

x